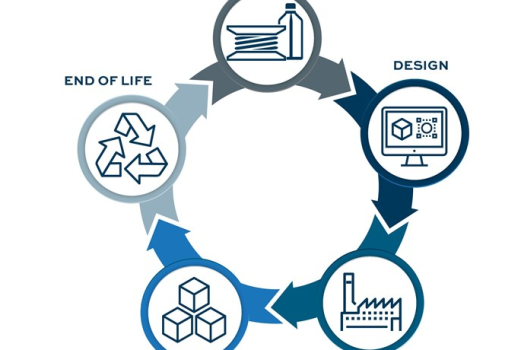

Recycling is the process of taking used materials and turning them into new products. It helps to reduce pollution and conserve resources.

There are many different types of recycling, but most involve sorting materials into groups and then using them to create new products.

Process of Paper Recycling

The process of recycling paper begins with sorting paper into different grades.

Step#1: The most common types of paper are mixed paper, newsprint, and cardboard.

Step#2: All paper is then sent to a pulping facility.

Step#3: At the pulping facility, the paper is mixed with water and turned into a slurry.

Step#4: The slurry is then poured onto a screen.

Step#5: The screen separates the pulp from the water.

Step#6: The pulp is then cleaned and de-inked.

Step#7: It is then formed into new sheets of paper.

Process of Metal Recycling

The recycling process of metals begins by sorting metals into groups.

There are three main groups: ferrous metals, non-ferrous metals, and precious metals.

Step#1: Ferrous metals, such as iron and steel, are attracted to magnets and are easily recycled.

Step#2: Non-ferrous metals, such as aluminum, copper, and brass, are not attracted to magnets and must be separated manually.

Step#3: Precious metals, such as gold and silver, are valuable and are usually recycled separately from other metals.

Steps in Recycling Metals

After the metals have been sorted, they are then cleaned and crushed into small pieces.

Step 1: The metal is fed into a furnace where it is melted down.

Step 2: The molten metal is poured into a mold to create new products.

Process of Wood Recycling

The recycling process of wood begins by sorting wood into different grades.

There are two main grades: hardwoods and softwoods.

Step 1: Hardwoods, like oak and maple, are used to make furniture and flooring.

Step 2: Softwoods including pine and cedar can be used to create paper and lumber.

After the wood has been sorted, it is then chipped into small pieces.

Step 3: The chips are then turned into pulp.

Step 4: The pulp is then formed into new sheets of paper or lumber.

Process of Glass Recycling

The recycling process of glass begins by sorting glass into different grades.

There are three main grades: clear glass, green glass, and brown glass.

Step 1: Clear glass is leveraged to make bottles and jars.

Step 2: Green glass is used for creating beer and wine bottles.

Step 3: Brown glass is helpful in making food jars and containers.

After the glass has been sorted, it is then crushed into small pieces.

Step 4: The crushed glass is then heated in a furnace.

Step 5: The molten glass is poured into a mold to create new products.

Process of Plastic Recycling

The recycling process of plastic begins by sorting plastic into different grades.

There are two main grades: thermoplastics and thermosets.

Step 1: Thermoplastics, such as polyethylene and polypropylene, can be melted and reformed.

Step 2: Thermosets like phenolic and epoxy, cannot be melted and must be crushed into small pieces.

After the plastic has been sorted, it is then cleaned and shredded into small pieces.

Step 3: The shreds are then melted down.

Step 4: The molten plastic is poured into a mold to create new products.

Recycling is the process of turning waste materials into new products. It helps to reduce pollution and conserve resources.

Once you have sorted the materials, you can begin the process of recycling. First, the materials are cleaned and then shredded into small pieces. Next, the shreds are melted down and formed into new products. Finally, the new products are cooled and ready to be used again.

Why Do You Need to Recycle?

Recycling conserves resources, saves energy, reduces pollution, and helps to create new jobs.

Conserving resources

It takes less energy and water to recycle materials than it does to produce new materials from scratch. For example, recycling one aluminum can saves enough energy to run a TV for three hours.

Saving energy

Recycling waste materials helps to save energy. For example, making new aluminum cans from recycled aluminum conserves 95% of the energy that would be required to make aluminum cans from scratch.